01-20

/2026

Environmental compliance has become a defining factor in modern asphalt production. Among all regulatory and operational concerns, dust and emissions stand out as the two most critical environmental challenges facing asphalt mixing plants today. While closely related, these issues require different control strategies, technologies, and management approaches.1. Understanding Dust in Asphalt ProductionDust is a solid particulate byproduct generated during material handling and processing. In asphalt plants, dust mainly originates from:Aggregate drying and screeningMaterial transfer and conveyingFiller handling and storageUncontrolled dust can affect air quality, reduce material utilization, and increase wear on plant components. It is also one of the most visible indicators of poor envi

01-13

/2026

With rising energy costs and stricter environmental regulations, energy-efficient asphalt mixing plants are becoming a strategic investment for modern road construction projects. By integrating advanced heating systems, intelligent controls, and optimized material handling, these plants significantly reduce fuel consumption and emissions while maintaining consistent asphalt quality.1. Optimized Heating Systems for Lower Fuel ConsumptionEnergy-efficient asphalt plants utilize advanced burner technologies and optimized drum designs to maximize heat transfer efficiency. Key features include:High-efficiency burners with precise flame controlOptimized drying drums that reduce heat lossImproved insulation to maintain stable operating temperaturesThese technologies ensure aggregates reach ta

01-05

/2026

As the road construction industry evolves, advanced automation in asphalt plants has become a key driver for both cost efficiency and environmental sustainability. Modern asphalt mixing plants equipped with automated control systems not only improve production consistency but also optimize energy consumption, reduce material waste, and minimize emissions—supporting greener and more economical road construction.1. Intelligent Process ControlAutomated asphalt plants integrate intelligent control systems to monitor and manage all stages of production:Aggregate feeding and weighing accuracyAsphalt temperature and mixing timeRAP (Reclaimed Asphalt Pavement) proportioning and blendingThis ensures consistent asphalt quality while reducing human error, which can lead to costly rework or mater

01-05

/2026

Modern infrastructure development increasingly emphasizes sustainability, efficiency, and long-term performance. As the demand for eco-friendly and durable road networks grows, smart asphalt plants have emerged as a cornerstone for achieving these goals. By integrating advanced automation, intelligent monitoring, and energy-efficient systems, smart asphalt plants not only produce high-quality asphalt but also contribute to sustainable and cost-effective infrastructure.1. Intelligent Monitoring for Consistent Asphalt QualitySmart asphalt plants are equipped with IoT-enabled sensors and monitoring systems that track:Asphalt temperature and mixing consistencyMaterial moisture content and aggregate proportionsMachine operational status and energy consumptionThis real-time data ensures con

12-30

/2025

With sustainability becoming a core requirement in modern road construction, RAP (Reclaimed Asphalt Pavement) recycling technologies are increasingly adopted worldwide. Among these solutions, hot asphalt recycling and cold asphalt recycling are the two most commonly used methods. Each approach offers distinct advantages, and choosing the right one depends on project scale, performance requirements, and environmental priorities.Understanding the differences between hot and cold RAP recycling helps contractors and decision-makers optimize both construction quality and cost efficiency.1. What Is Hot Asphalt Recycling?Hot asphalt recycling involves reheating reclaimed asphalt materials and mixing them with virgin aggregates and bitumen at high temperatures. This method is typically integr

12-26

/2025

As infrastructure investment continues to grow worldwide, governments are under increasing pressure to balance road quality, construction cost, and environmental responsibility. Traditional road construction methods often rely heavily on virgin materials and high energy consumption, which leads to rising costs and higher carbon emissions. In response, many governments are actively promoting RAP (Reclaimed Asphalt Pavement) technology as a key solution for modern road projects.1. Meeting National Sustainability and Carbon Reduction GoalsOne of the main reasons governments support RAP technology is its contribution to carbon reduction and sustainability targets. By reusing reclaimed asphalt materials, RAP:Reduces the demand for new aggregates and bitumenLowers energy consumption during

12-26

/2025

As global infrastructure development accelerates, sustainability has become a key priority in road construction. Governments, contractors, and developers are increasingly seeking solutions that reduce environmental impact while maintaining performance and durability. RAP (Reclaimed Asphalt Pavement) technology has emerged as one of the most effective approaches to achieving these goals.By integrating RAP technology into asphalt production, modern asphalt mixing plants—such as those developed by TTM (Tietuo Machinery)—support greener, more efficient, and cost-effective road construction.1. What Is RAP Technology in Asphalt Production?RAP refers to reclaimed asphalt materials recovered from existing pavements during maintenance or rehabilitation work. These materials can be:Processed an

12-19

/2025

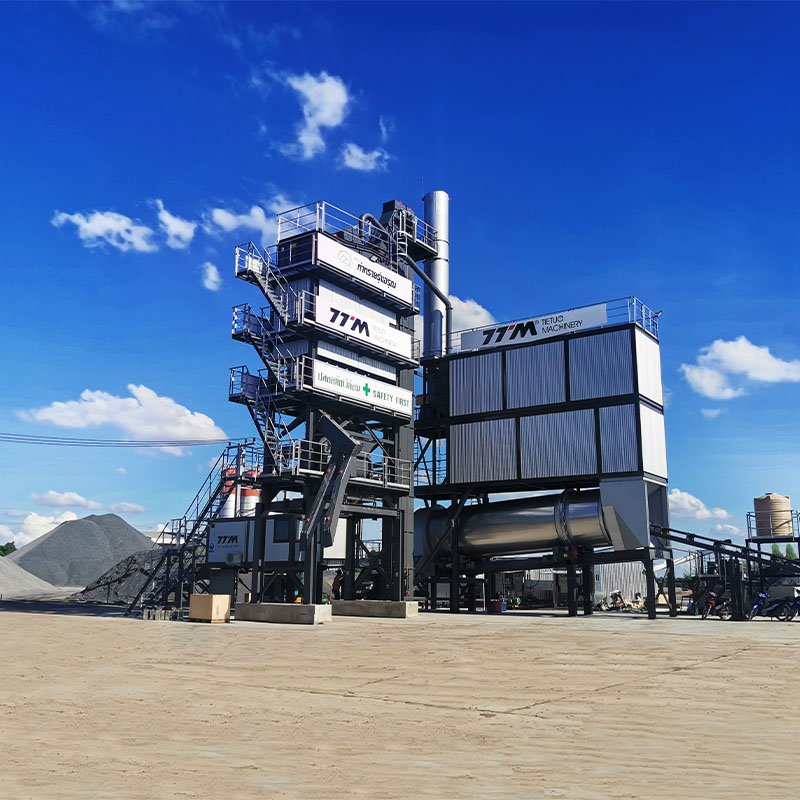

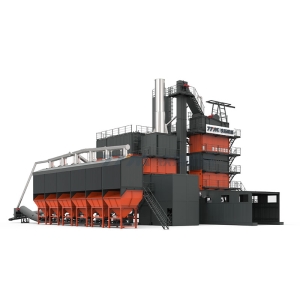

As cities around the world evolve, the concept of smart urban infrastructure is becoming central to modern construction. Asphalt mixing equipment is no longer just about producing asphalt; it now plays a pivotal role in efficient, intelligent, and sustainable urban road construction. TTM (Tietuo Machinery) offers advanced asphalt mixing plants designed to integrate with smart city initiatives, delivering high-quality asphalt production while optimizing operations.1. Smart Monitoring and IoT IntegrationIntelligent asphalt mixing plants allow real-time monitoring of:Asphalt temperature, humidity, and mixing consistencyEquipment energy consumption and operational statusPredictive maintenance alerts to avoid downtimeWith IoT-enabled systems, city planners and contractors can manage multip

12-19

/2025

Asphalt mixing equipment has become an essential part of modern infrastructure development. TTM (Tietuo Machinery) provides advanced asphalt plants that are not only efficient and intelligent but also versatile enough to be applied in a wide range of construction projects. Understanding the various applications can help contractors and developers maximize their investment and optimize project outcomes.1. Highway and Expressway ConstructionHigh-capacity asphalt mixing plants are ideal for large-scale highway and expressway projects, where continuous production and consistent quality are critical. TTM’s modular design ensures:Steady asphalt output for long stretches of roadwayEfficient energy consumption for large-scale productionAdaptability to varying asphalt grades and project specificati

12-12

/2025

Selecting the right asphalt mixing plant is critical for ensuring project efficiency, quality, and cost-effectiveness. With various types and capacities available, understanding the project requirements and equipment features can help contractors and developers make the best choice. TTM (Tietuo Machinery) provides a wide range of asphalt mixing solutions designed to meet different project needs, from urban roads to large-scale highways.1. Determine Your Project ScaleThe size and type of your project directly affect the choice of equipment:Large-scale highways and expressways: Require high-capacity, continuous asphalt plants that can produce consistent output for extended construction periods.Urban and residential roads: Compact or modular asphalt plants are ideal for city streets wher