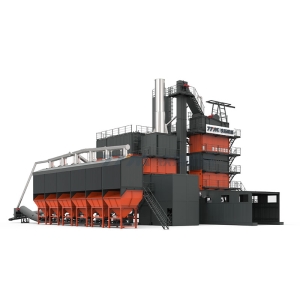

Selecting the right asphalt mixing plant is critical for ensuring project efficiency, quality, and cost-effectiveness. With various types and capacities available, understanding the project requirements and equipment features can help contractors and developers make the best choice. TTM (Tietuo Machinery) provides a wide range of asphalt mixing solutions designed to meet different project needs, from urban roads to large-scale highways.

1. Determine Your Project Scale

The size and type of your project directly affect the choice of equipment:

-

Large-scale highways and expressways: Require high-capacity, continuous asphalt plants that can produce consistent output for extended construction periods.

-

Urban and residential roads: Compact or modular asphalt plants are ideal for city streets where space may be limited.

-

Industrial pavements or airport runways: High-performance plants capable of producing specialized asphalt mixes are necessary for heavy-duty applications.

Understanding project scale ensures that the asphalt plant can meet production demands without over-investing in unnecessary capacity.

2. Consider Mobility and Installation

Some projects require temporary or remote asphalt production:

-

Mobile asphalt plants: Perfect for short-term or remote projects, they are easy to transport and install.

-

Stationary modular plants: Suitable for long-term projects with high production requirements.

Choosing the right installation type can save time, reduce logistics costs, and improve project flexibility.

3. Evaluate Production Efficiency and Control

Modern construction demands efficiency and precision:

-

High-efficiency mixing systems: Ensure consistent asphalt quality and faster production cycles.

-

Smart control systems (IoT-enabled): Allow real-time monitoring, predictive maintenance, and remote operation, reducing downtime and operational costs.

TTM asphalt plants are designed with optimized mixing technology and intelligent control, making them suitable for a variety of infrastructure projects.

4. Focus on Environmental and Energy Considerations

Sustainability is increasingly important in construction:

-

Dust collection and emission reduction systems: Minimize environmental impact and comply with regulations.

-

Energy-efficient burners and heating systems: Lower fuel consumption and operating costs.

-

RAP (Reclaimed Asphalt Pavement) integration: Reduce raw material usage and promote green construction practices.

Selecting equipment with strong environmental features can enhance project compliance and corporate responsibility.

5. Match Asphalt Plant Type to Project Requirements

Different project conditions may require specific plant types:

-

Stationary Asphalt Plants: Best for long-term, high-volume projects.

-

Mobile Asphalt Plants: Ideal for flexible, on-site production.

-

RAP-Compatible Plants: Suitable when recycling reclaimed asphalt is a priority for cost savings and sustainability.

Considering the project location, volume, and material requirements helps contractors choose the most suitable plant without compromising efficiency or quality.

Contact TTM: Expert Guidance for Your Asphalt Projects

TTM provides a full range of high-performance, intelligent, and eco-friendly asphalt mixing plants, suitable for all types of projects.