Environmental compliance has become a defining factor in modern asphalt production. Among all regulatory and operational concerns, dust and emissions stand out as the two most critical environmental challenges facing asphalt mixing plants today. While closely related, these issues require different control strategies, technologies, and management approaches.

1. Understanding Dust in Asphalt Production

Dust is a solid particulate byproduct generated during material handling and processing. In asphalt plants, dust mainly originates from:

-

Aggregate drying and screening

-

Material transfer and conveying

-

Filler handling and storage

Uncontrolled dust can affect air quality, reduce material utilization, and increase wear on plant components. It is also one of the most visible indicators of poor environmental control.

2. Understanding Emissions in Asphalt Production

Emissions refer to gaseous byproducts released during fuel combustion and heating processes. Common emissions include:

-

Carbon dioxide (CO₂)

-

Nitrogen oxides (NOₓ)

-

Volatile organic compounds (VOCs)

Unlike dust, emissions are often invisible but have long-term impacts on climate, air quality, and regulatory compliance.

3. Key Differences Between Dust and Emissions Control

Although both are environmental concerns, dust and emissions require distinct control methods:

| Aspect | Dust Control | Emissions Control |

|---|---|---|

| Physical form | Solid particles | Gases |

| Main source | Material handling | Fuel combustion |

| Control methods | Filtration, enclosure | Clean combustion, efficiency |

| Visibility | Highly visible | Often invisible |

| Regulatory focus | Workplace & local air | Climate & regional air |

Understanding these differences is essential for designing effective environmental strategies.

4. Integrated Environmental Control Strategies

Modern asphalt plants increasingly adopt integrated solutions that address both dust and emissions simultaneously, such as:

-

High-efficiency baghouse filtration systems

-

Optimized airflow and negative pressure design

-

Energy-efficient burners and heating systems

-

RAP integration to reduce heating demand

This holistic approach ensures compliance while improving overall production efficiency.

5. Why Environmental Challenges Are Shaping Asphalt Plant Design

Global environmental regulations are driving asphalt plant manufacturers to rethink traditional designs. Today’s plants must deliver:

-

Lower emissions per ton of asphalt

-

Stable dust control under high production loads

-

Intelligent monitoring and automated adjustments

These requirements are transforming asphalt plants into cleaner, smarter, and more sustainable production systems.

Dust and emissions represent the two core environmental challenges in asphalt production, each requiring specialized control technologies. By understanding their differences and adopting integrated environmental solutions, asphalt producers can meet regulatory requirements while maintaining efficient and reliable operations.

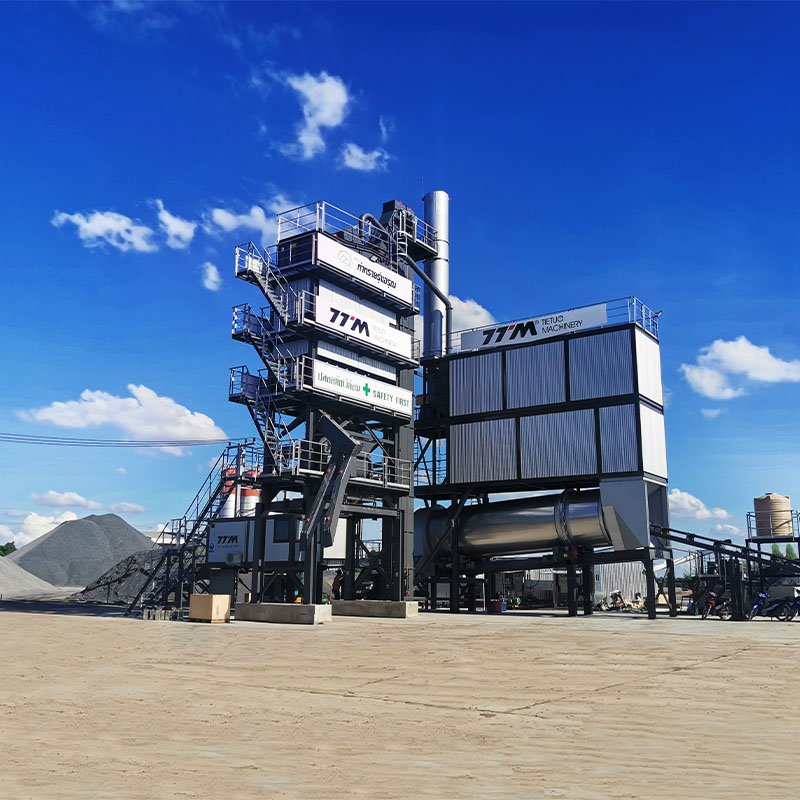

TTM (Tietuo Machinery) focuses on developing environmentally responsible asphalt mixing plant solutions that help customers manage both dust and emissions effectively in modern infrastructure projects.